Functional Office Solutions Designed To Enhance Productivity And Meet Corporate Needs.

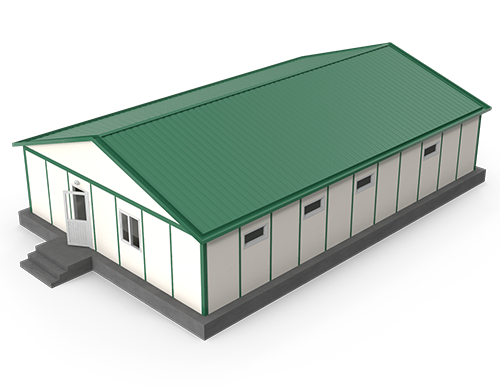

High-Durability, Modern Structures Developed For Public Services And Social Use.

Safe, Energy-Efficient Residential Systems Offering Comfortable Living Spaces.

Light steel buildings provide high structural strength, rapid installation and long-term durability, making them an ideal solution for modern residential, commercial and industrial projects. PRECO MODULAR designs and manufactures light steel structures engineered to deliver superior load-bearing capacity, excellent seismic performance and efficient thermal insulation. With flexible architectural options, environmentally friendly materials and fast construction timelines, our light steel systems offer a reliable and economical alternative to traditional reinforced-concrete buildings. PRECO MODULAR ensures safe, resilient and high-quality steel structures tailored to diverse project requirements.

Prefabricated buildings are engineered for long-term durability and can be safely used for an average of 40–60 years depending on maintenance, climate conditions and usage. Factors such as wind load, humidity, rainfall and structural care may influence lifespan. PRECO MODULAR buildings are manufactured using high-quality steel systems and durable wall materials, helping extend their service life significantly.

Yes. PRECO MODULAR prefabricated structures are designed as modular systems that can be dismantled, transported and reinstalled at a different location. During re-assembly, some connection materials may require replacement depending on usage and site conditions. Up to 10% renewal of mounting components is typically sufficient.

Like all building types, prefabricated structures benefit from periodic maintenance. Routine inspections of panel systems, sealing elements and connection points help maintain long-term performance. Any small surface cracks or sealant wear that may occur over time can be easily repaired. With proper care, PRECO MODULAR buildings maintain their structural integrity for many years.

PRECO MODULAR homes and offices use high-performance insulation systems. Exterior walls are produced with insulated sandwich panels or fibercement-clad systems that provide effective thermal and acoustic comfort. Additional insulation materials such as mineral wool, EPS or rock wool may be used depending on project requirements. These systems help maintain comfortable indoor temperatures throughout all seasons.

Production is carried out in our factory under controlled conditions and is generally completed within a short period. Depending on the project size, on-site installation can take approximately 10–25 days. After installation, interior finishing and painting usually take an additional 1–3 days based on the building's square meter. With proper planning, the entire process from manufacturing to handover can be completed quickly and efficiently.

Building permit requirements vary by region. In many areas, prefabricated buildings follow the same regulations as conventional structures. Your local municipality or construction authority can provide the necessary guidelines. PRECO MODULAR assists customers with the technical documents needed during the permit process.

Standard prefabricated homes can be produced as single-story or two-story structures. In light-steel building systems, up to three stories may be feasible depending on engineering requirements, soil conditions and local regulations.

Pricing depends on the building size, wall system type, insulation level, roof system, window and door selections, interior finishes and additional design features. Prefabricated buildings generally offer a more economical solution compared to concrete structures due to faster production, shorter installation times and reduced labor costs. PRECO MODULAR provides transparent quotations tailored to each project.

Yes. PRECO MODULAR structures are engineered to perform in various climatic regions, from extreme heat to heavy snowfall. High-insulation wall systems, durable steel framing and weather-resistant cladding ensure strong performance even in demanding environmental conditions.

Absolutely. Customers can select floor plans, façade colors, window placements, exterior finishes, roofing types and interior layouts. PRECO MODULAR offers complete flexibility to ensure every building meets specific lifestyle, operational or aesthetic preferences.

PRECO MODULAR buildings are designed using engineered steel systems, providing enhanced seismic performance compared to traditional masonry structures. Lightweight construction reduces lateral loads, and high-strength connections ensure structural stability during earthquakes.